Maschinen-unabhängige CAM-Software

CAM software for furniture production | CAM software for door production | CAM software for window construction | CAM software for facade construction | Nesting CNC software |

NC-Hops: The complete CAD/CAM package with variable macro technology

This maximizes productivity and ensures a fast path to the finished product.

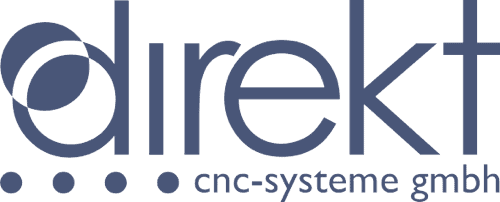

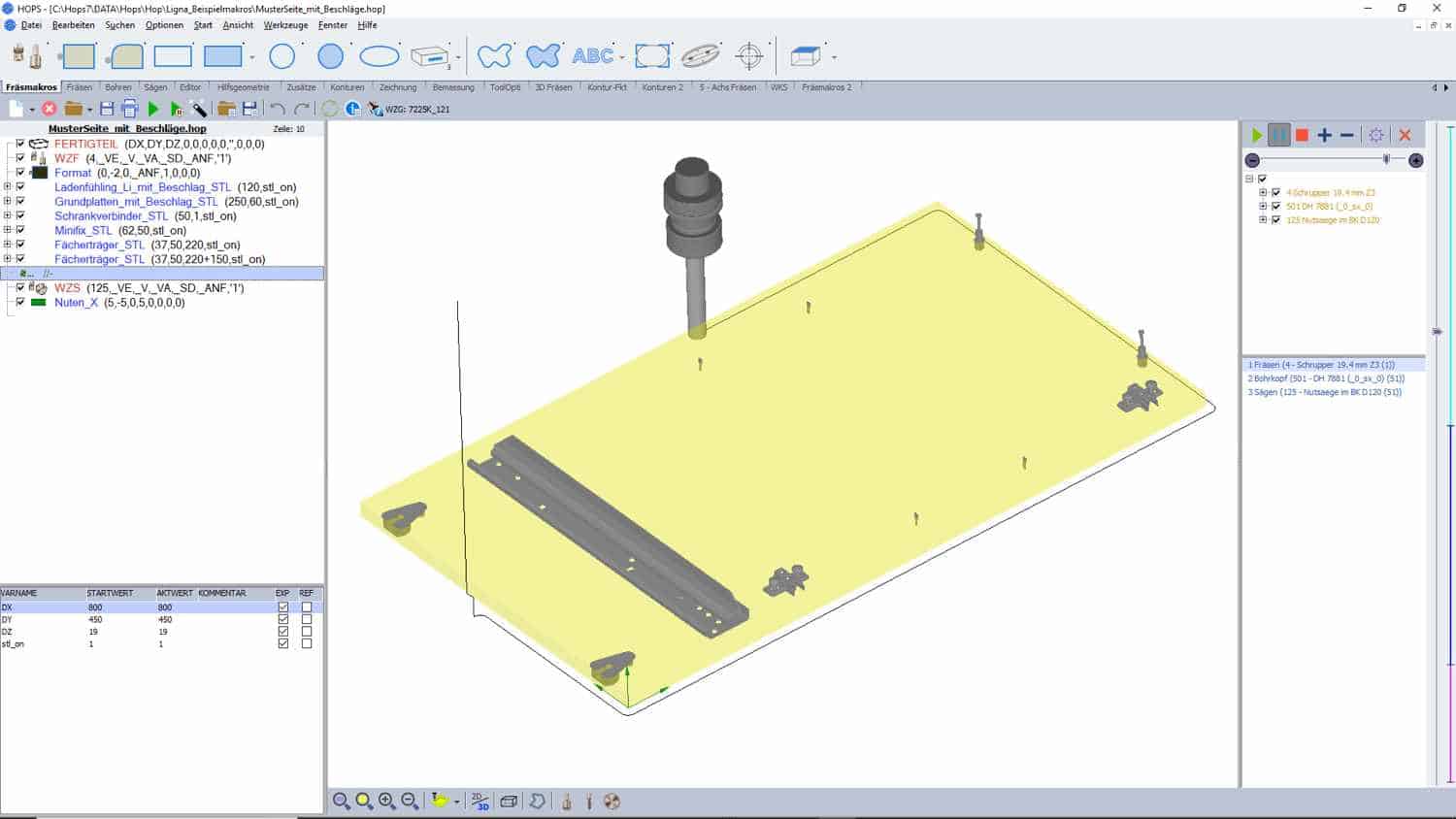

Powerful macro technology and the always up-to-date graphical display support the user in creating fixed or variable components.

Machine-independent software

Quick and easy input in dialog with EasySnap function

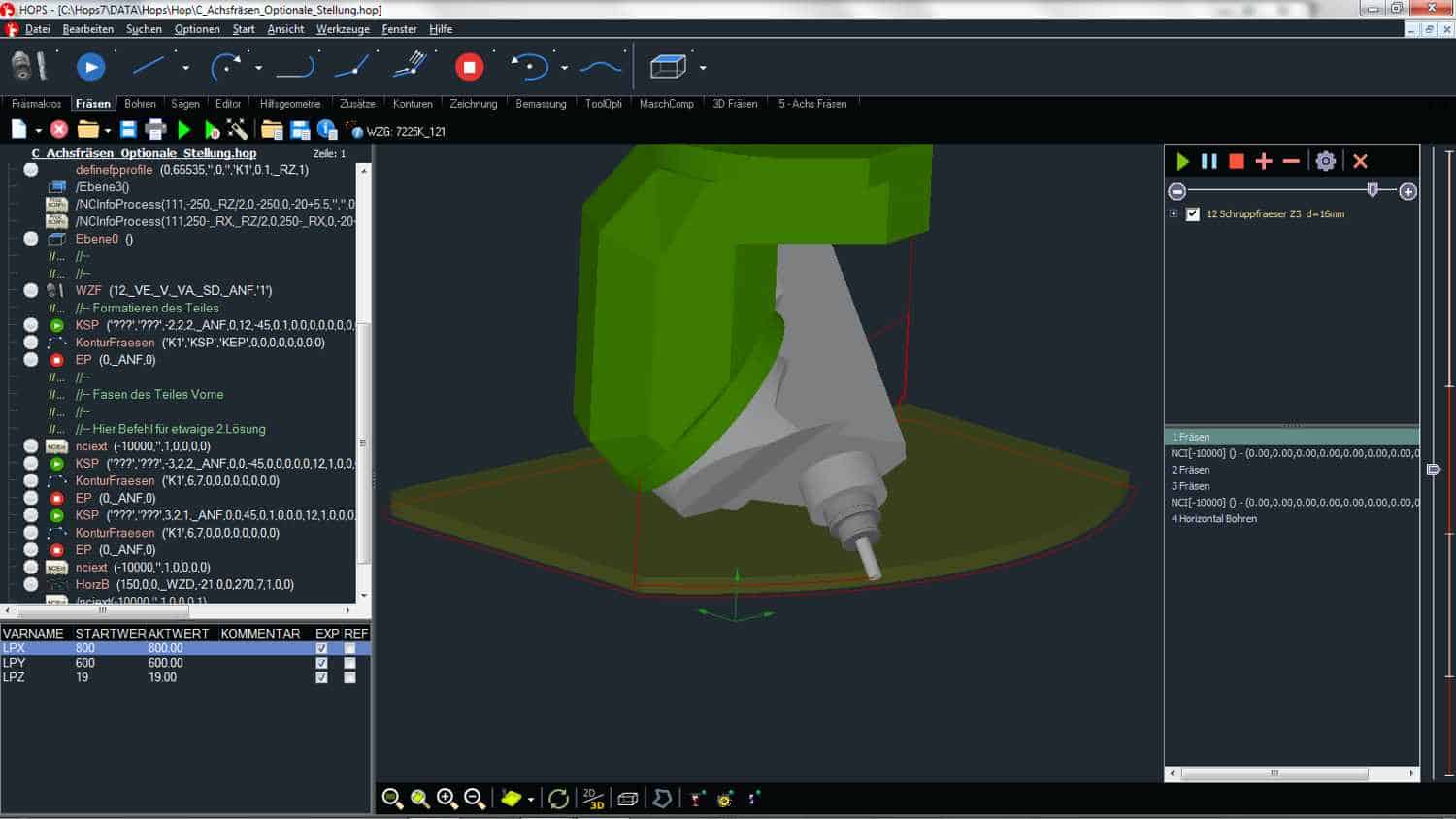

Spatial 3D Visualization & Simulation

Flexible library concept

Support up to 5 axes and Multihead

Intelligent postprocessor concept

Integration into existing environment

Partner of all leading machine manufacturers

Application areas

Tool-specific safety distances, approach distances and feeds guarantee a high level of safety. The integrated 3-D view shows traverse paths, the tool position and clearly displays the entire workpiece. The workpiece can be rotated to any desired view at the click of a mouse.

The machine-independent machining strategies are reliably translated by the system into the language of the respective control types.

CNC furniture production

CNC interior fittings

CNC door production in leaf and frame production

CNC staircase production

CNC window construction

CNC facade construction

Interior fittings for ships and yachts

Truck trailer and caravan production

Acoustic components

flexible library concept

User interface

NC-HOPS als innovatives, leistungsstarkes Programm, gibt dem Anwender die Möglichkeit sein Produkt kreativ und einfach zu gestalten.

Register fassen die Funktionen zu Bearbeitungsgruppen zusammen. Damit wird ein schnelles Auffinden der benötigten Bearbeitungen erreicht.

Umfangreiche Funktionen und die Möglichkeit zur Erweiterung mit eigenen Makros, bieten eine optimale Integration in den Fertigungsprozess.

We deal exclusively with tasks in wood, plastic and aluminium processing CNC technology.

Option modules for NC-HOPS

Optimizations such as part nesting, tool and process optimization, part document plans, suction cup position proposal, clamp position calculation, data transfer from ERP/PPS systems shorten processing times and support handling of the machine.

Software Integration and Engineering

Wait for what?

Request more info & individual demo

We will show you our CAM software NC-HOPS live on your screen.

In dialogue with our employees, you will learn about the latest CAM technology and receive answers to your questions.

Please feel free to request further information and/or a callback without obligation!

Uncomplicated and fast

Non-binding and free of charge

Clarify questions directly

Test individual use cases

Software Integration and Engineering

A proven post-processor concept enables the control of all NC technologies up to complex machining centres. Multi-channel and 5-axis machining is standard for us.

The development of import and export interfaces, the integration into a heterogeneous machine environment and the optimization of machine processes is the daily work of our engineering department.

The focus is always on the efficiency, safety and user-friendliness of a machine. The development of an emergency stop scenario is just as important as the automatic production sequence.

Our partners appreciate our competence as well as our clear and reliable planning.

This is also based on fixed project costs.